Food science and technology research helps to ensure a safer global food supply

Home cooks and professional chefs alike the world over can thank Monica Ponder, assistant professor of food science and technology in the College of Agriculture and Life Sciences, for a safer supply of spices.

Spices are typically grown in developing countries where opportunities for tainting the product from infected workers and pests are increased due to poorer sanitation practices, leaving the product open to contamination from birds and others animals, even the farmers themselves. There is minimal processing of spices after harvest that would otherwise result in destruction of human pathogens. This presents a contamination risk for the food industry from pathogens such as Salmonella because spices are frequently added to finished products.

“Spices are an emerging vehicle for disease in the food sector,” said Ponder.

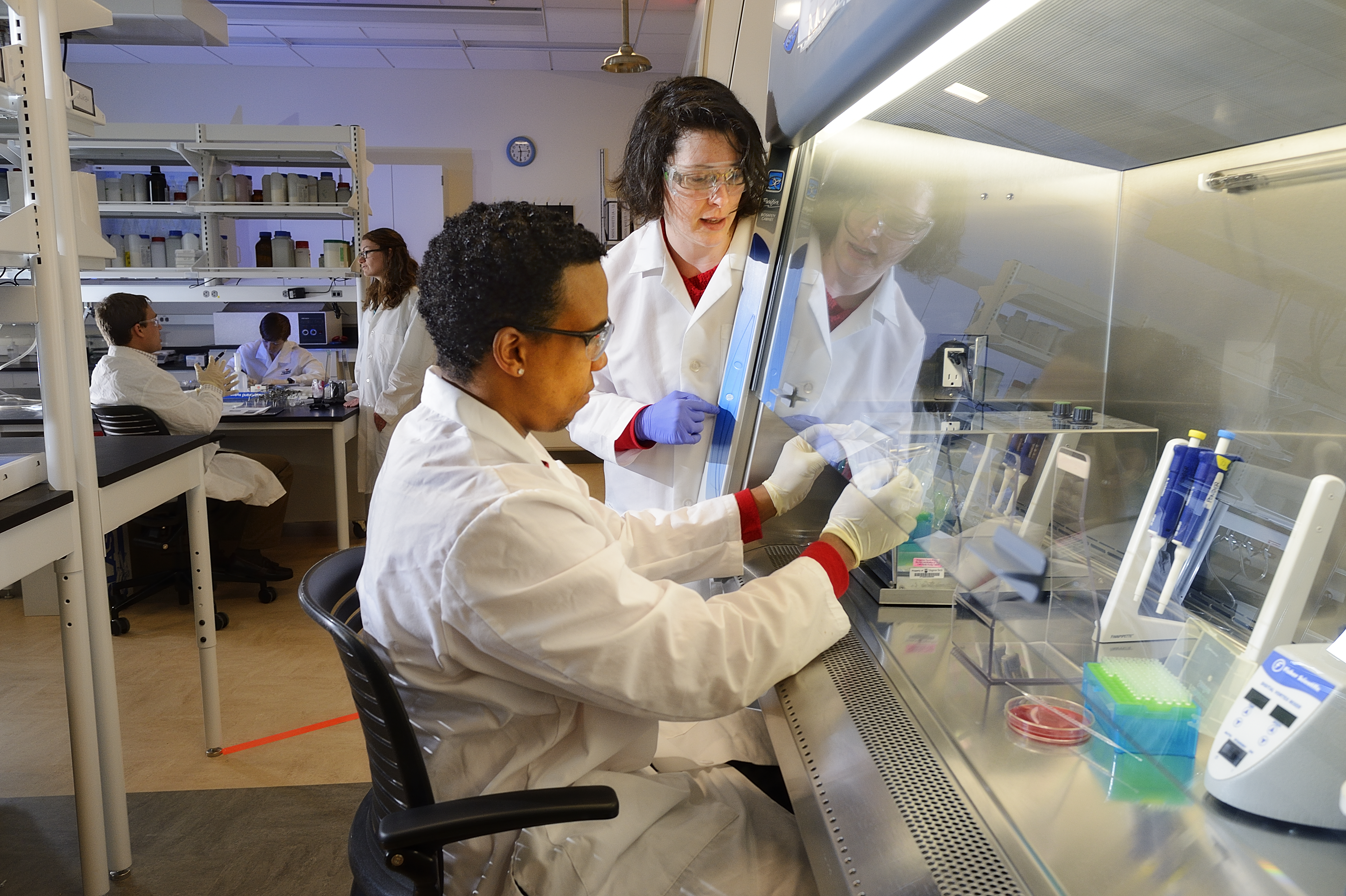

Ponder will soon be able to work in a biosecurity level 2 pilot plant facility to develop strategies to combat Salmonella contamination in the new Human and Agricultural Biosciences Building 1. It is one of only several labs rated as such in the country.

One of the other advantages of working in the newly constructed facility is the large open lab space, some of which will allow her to test large pieces of equipment used for drying spices like those used for industrial processing in the 93,860-square-foot building.

Ponder will also have ample opportunity to collaborate with her colleagues, Robert Williams, associate professor of food science and technology, and Kumar Mallikarjunan, associate professor of biological systems engineering, to develop strategies to kill Salmonella on spices.

Ponder’s research is helping to ascertain how and why spices become contaminated with disease-causing bacteria such as Salmonella. She’s studying how the pathogen travels through the supply chain tightly adhered to whole spices within biofilms. Biofilms formed during growth or during processing may improve survival of Salmonella by encasing it within layers of polysaccharides, protecting the cells.

“We are trying to understand how biofilms form and how they help Salmonella’s survival,” she said.

Salmonella is commonly associated with high-moisture foods like meats such as chicken and beef, but spices and other low-moisture foods are newly recognized sources of Salmonella disease outbreaks. While the number of Salmonella isolated from spices and other low-moisture foods found in disease outbreaks is much lower than other foods such as meat, the potency is much greater, indicating the lower moisture environments such as those where spices are processed tend to increase the virulence of the pathogen.

One of the questions Ponder is asking is, how does Salmonella continue to thrive in low-moisture environments and how does this affect its ability to cause disease?

The United States is one of the world’s largest spice importers, bringing in 326 kilotons in 2012 valued at $1.1 billion. The Food and Drug Administration was prompted to look deeper into Salmonella contamination of spices when major outbreaks occurred in the United States between 2007 and 2009, including one in which 272 people were sickened by the peppercorns in salami. The FDA sampled 2,844 imported dry spice shipments from 2007 through 2009 and found about 7 percent tested positive for Salmonella, twice the rate of other FDA-regulated food products, the agency said in the report.

“One of my big projects is making validated processes that the spice industry can use to assure that Salmonella on whole black peppercorns and cumin seeds is eliminated,” said Ponder.

One of Ponder’s other research initiatives, exploring nanoiron and how it affects gut microbiota in the human body, will also be helped by her move to the building. The move will facilitate her work with colleagues in biological systems engineering who are also working within the increasingly popular field of nanotechnology.

For now, though, Ponder is working to understand what makes Salmonella the persistent pathogen that it is. In the future her research may be used to help her consult for private companies who have issues with contaminated products and equipment.

“We are expanding the capability of companies to combat Salmonella and other human pathogens in foods by providing a research space where the effects of processing can be determined on live pathogens,” said Ponder.

“The Human and Agricultural Biosciences Building 1 will allow companies to find vulnerabilities in elimination and containment strategies in a controlled environment,” she said. “The research conducted in this facility will make for a safer global food supply.”

Written by Amy Loeffler.

.jpg.transform/m-medium/image.jpg)